If you rely on electric motors to power your business, consistent performance is key to keeping productivity and profit margins high.

Unfortunately, so many Clients we are called out to are running their motors inefficiently – often only paying attention to their motors when they fails or begins to show drastic underperformance.

To avoid downtime and keep your business moving, we’ve pulled together a 5 step checklist for improving AC and DC motor performance.

When businesses go through periods of growth, one of the things that rarely changes is their motor set up. Failing to ensure your motors are still the right ones for the job greatly increases the risk of a fault.

To ensure your setup isn’t destined to fail, you should carry out a motor assessment, documenting how many motors you have, their last service or inspection? how old they are, their power ratings, the applications and load requirements?

From this, you’ll be able to ascertain whether or not your motors are being used correctly, or being subject to higher or lower loads than recommended.

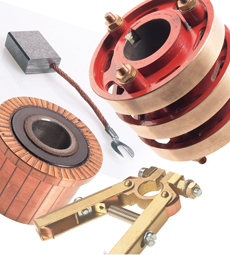

Carbon brushes are an essential component within DC motors that are often neglected., Failure to replace carbon brushes at the correct time can result in poor performance, build up of carbon dust, damage to vital components and even complete motor failure.

If you notice excessive sparking from brush contact with the motor’s commutator, a decrease in performance from your motor, or a build up of carbon dust – it’s time to inspect and potentially replace your carbon brushes.

As well as replacing carbon brushes when required, you should ensure that you are using the right kind of brush for your motor. Using the incorrect grade for the application or one that is poorly fitted results in premature wear, sparking, additional heating and ultimately damage to the motor.

For more information, read our blog on the most common causes of fault for carbon brushes in DC motors.

Any unusual or excessive noise or vibration is a sign that your motor is not operating correctly. This can indicate loose parts within the motor or with the mounting arrangement.

Prolonged operation with excessive noise and vibration can result in a number of issues including overheating, damaged components, carbon brush sparking, carbon brush damage and winding faults –leading quickly to failure of your motor and costly remedial work.

As well as taking note of any excessive noise and vibration from your motor, consider professional noise and vibration testing to ensure that any abnormal behaviour from your motor doesn’t result in a serious issue.

If you are monitoring the performance of your machinery, then you may notice if the normal motor load current has increased or if it does not operate in the usual way.

Whilst this isn’t always noticeable, you may be able to identify an increase in energy bills or production costs, which could be an early sign that one of your motors is underperforming.

Essential maintenance is a must for ensuring motor performance and efficiency remains as expected. Preventative maintenance contracts often come at a fraction of the cost of emergency repair and ensure zero costly downtime for your operation.

In addition to having a professional regularly inspect your motor, you should frequently do the following:

As well as reducing overall efficiency within your business, running a motor inefficiently has a number of other drawbacks:

At Mawdsleys, we offer a complete service for AC and DC motors from installation to emergency repair – we can also offer preventative maintenance contracts to keep performance high.

For more information on any of our AC & DC motor services, give one of our expert team a call today on 0117 955 2481 or fill out a contact form and we’ll get back to you.