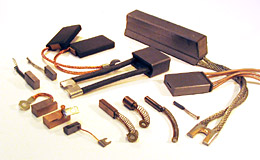

Mawdsleys can now offer on site advice concerning “Carbon Brush Wear” on your DC Motors. By reviewing your Carbon Brushes we are able to determine if the Brushes are installed correctly, giving problem free operation or if the Brushes have signs of wear or damage due to electrical under loading, overloading, winding faults, voltage surges, sparking or issues with the commutator.

Mawdsleys can now offer on site advice concerning “Carbon Brush Wear” on your DC Motors. By reviewing your Carbon Brushes we are able to determine if the Brushes are installed correctly, giving problem free operation or if the Brushes have signs of wear or damage due to electrical under loading, overloading, winding faults, voltage surges, sparking or issues with the commutator.

Carbon is a soft metal and brushes are designed to wear out over time, the reason a soft metal is used is to reduce the amount of damage caused to the commutator through friction.

Once the carbon brushes are completely worn the motor will begin to underperform before failing – running a motor with worn carbon brushes can result in extensive damage to the motor.

Experiencing problems with your carbon brushes? We can help. Years of experience allow us to determine the problem and give advice on best the solutions available.

To find out more, give us a call today on 0117 955 2481 or fill out a contact form and we will get back to you.