Explosion proof motors, otherwise referred to as ex motors or ATEX motors are a special type of motor that are designed to be used in hazardous environments where the risk of an explosion is higher.

Whether it’s high humidity, extreme temperatures or dust in the air, an explosion proof motor has safety features in line with the ATEX directive to keep the environment safe.

Find out more about potentially explosive atmospheres, the safety standards that govern them and the types of motor that can be used to eliminate the risk of an explosion in our latest blog post.

Under the ATEX (ATmosphere EXplosible) directive which covers equipment used in potentially explosive atmospheres, a potentially explosive atmosphere exists when “a mixture of air gases, vapours, mists, or dusts combine in a way that can ignite under certain operating conditions”.

With electric motors, the most common causes of explosion are the surface becoming so hot during operation that it causes ignition or a single arc from a motor malfunction causing ignition.

For this reason, equipment such as motors that are used in these atmospheres must be specially designed so that they will not cause the atmosphere to ignite, with protections against environmental hazards such as dust, fire and, moisture.

Examples of these potentially dangerous environments include fixed offshore platforms, mines, flour mills, wastewater processing plants, workshops that use spray paint and food production lines.

There are two European Directives for controlling explosive atmospheres, these are known as ATEX. ATEX is implemented in the UK through DSEAR, the Dangerous Substances and Explosive Atmospheres Regulations, 2002. The two directives are:

An ATEX certification is required in order to work safely on explosion proof motors. At Mawdsleys, all of our specialist engineers are ATEX certified and can work on all types of ex motor.

There are several types of explosion proof motor for use in different environments. The most common types of protection offered by ex motors are:

The most suitable motor for your operation will be dependent on the hazards present within the environment and the job the motor is required to perform.

A key property of ex motors that makes them suitable in potentially explosive atmospheres is that they can protect against moisture and solid foreign objects.

If dust, water, or a larger foreign object enters a motor it can cause, damage, motor failure or even a spark or flame that could result in an explosion.

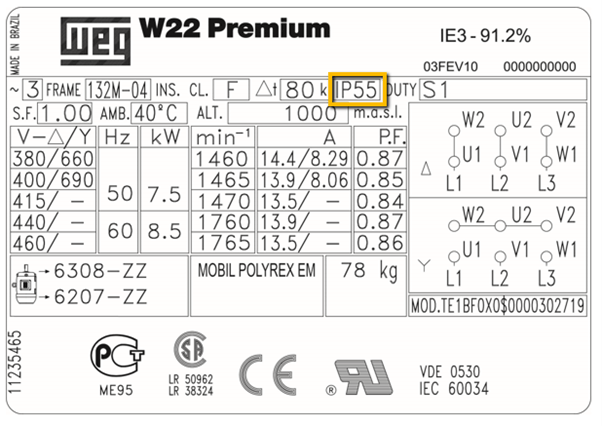

The degree of protection offered by ex motors is shown by the IP rating which will be found on the motor nameplate. The IP rating is made of two digits which show how well the motor is protected against both water and solid foreign objects.

Read our detailed blog post to find out more about motor ingress protection ratings.

On an ATEX motor nameplate, you will also find the information relating to the motor’s construction and level of protection. Under the ATEX directive, the following will be present on an ex motor:

ATEX is an abbreviation for the term ATmosphere EXplosible and is the name commonly given to two European Directives regarding controlling explosive atmospheres.

In the UK, employers are responsible to eliminate or control the risks from explosive atmospheres in the workspace. ATEX applies to all mechanical or electrical equipment used in these atmospheres, including electric motors.

If you have motors operating in a potentially explosive environment, it is critical that these motors have the correct safety features to ensure there is no risk of an explosion.

At Mawdsleys, our ATEX certified engineers offer a complete ex motor service including installation, ongoing maintenance, and repairs to ensure your motor is always running optimally.

For more information about our service, give one of our team a call today on 0117 955 2481 or fill out a contact form and we will get back to you.