From the start of this year, we have been busy refurbishing and setting up our new workshops to construct a state of the art motor rewind and repair facility for our customers in our new location. You can see here when we first got the keys at the end of last year, just how much work needed to be done!

After lots of hard work, we’re proud to have completed our new premises to improve efficiencies within our business and continue delivering an industry-leading service to our customers. Take a tour of our new premises and the range of high tech, professional facilities we have to offer.

It all starts here, upon arrival, customers are greeted in our reception area. To us, the Mawdsleys logo represents the hallmark of quality in motor and electrical rewind and repair.

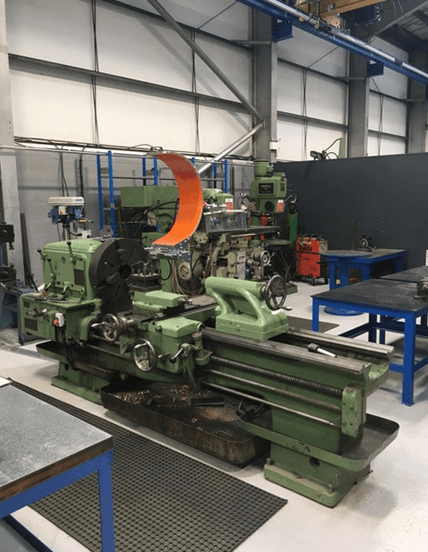

When motors, generators and other associated rotating equipment first comes into the workshop, it is taken to the machine department to be inspected, assessed and stripped down.

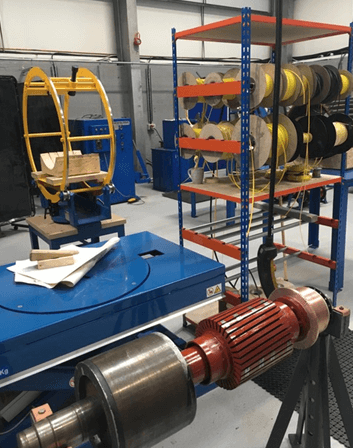

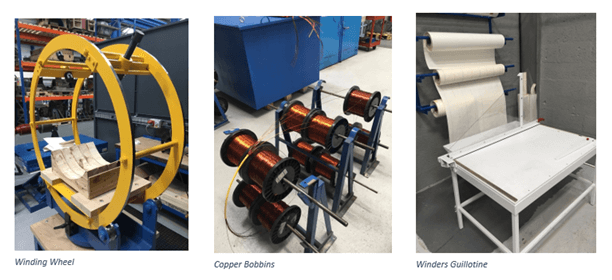

Within the winding department, we carry out full motor rewinds on AC Motors, DC Motors and Armatures. Within this department, our engineers use a winding wheel, winders guillotine and copper bobbin to carry out motor rewinds on any kind of electric motor.

Before the rotating machinery is reassembled, it is sent for balancing to the required levels and standards. Using our in-house balancing machine, we can balance motor components to very high standards of precision. These components often include motor rotors, flywheels, fans, couplings and armatures.

To ensure motors are fit for purpose and can withstand their usual operating conditions, they are put through their paces in our state of the art test area. Here we carry out tests including noise and vibration testing to ensure the motors are compliant with industry standards. Pictured below is the test area itself and the dual motor test panel.

Work in Progress Racking System

Work in Progress Racking System Our racking system assists in the flow of work coming through the workshop and helps keep our turnaround time low. Below you can see the various motors and associated components separated into job lots.

Once motors have been rewound or repaired, they are taken to our spray booth to have them looking good as new. The ventilation system you see installed here prevents any fumes from spreading around the workshop.

Here we have several different wash down stations kitted out with the tools needed for washing down all motor components.

Finally, we have the secure stock area. Here we keep all of our spares, parts and other stock. Not only does this secure room assist in ensuring we have the right parts, but it also helps keep our stock secure from theft.

Our state of the art workshop allows us to be pioneers in our field and provide a leading service nationally. To find out more about any of our services, please give one of our expert team a call today on 0117 955 2481 or fill out a contact form and we’ll get back to you.